Laminate Film TECHNOLOGY

ID Card Laminate Films

Laminating a photo identification card is not new. The industry has been laminating an additional layer of film over a card’s printed surface since the dawn of digital card printers. However, each manufacturer uses their own laminate film vernacular. There are three basic types of laminate films that are used in the industry.

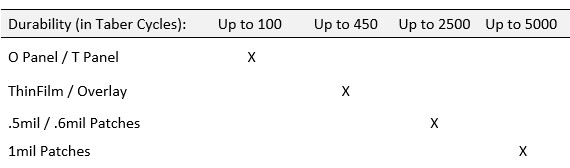

Ribbon Overlay: ID card printer’s ink ribbon includes an “O” or “T” panel – YMCKO or YMCKT. This O panel is the base level of card lamination. During the printing process, the printer’s thermal head transfers the O panel onto the card’s printed surface. This very thin layer is meant to reduce card fading and dye migration and offer a low level of abrasion resistance. Below is a durability chart detailing the O panel’s resistance to Taber Testing.

ThinFilm Laminate: The next step up in lamination requires a dedicated laminator to apply the film. As seen on the SMART-51L or SMART-81L, the laminator is attached to the printer, so it is a one-step process. Click the print button and the system will print and laminate in one pass.

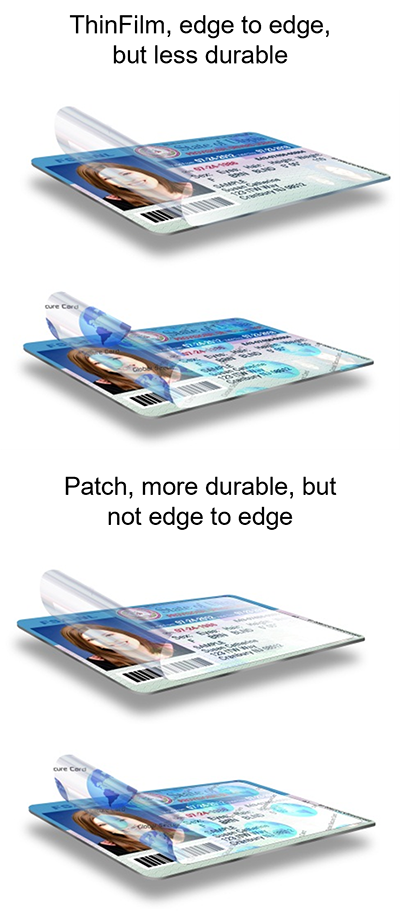

ThinFilm, also known as overlay or varnish by other manufacturers, provides an edge-to-edge protective layer covering the entire card. ThinFilm can be clear, offering protection only, or can be holographic (HRI – what is HRI?) to introduce security features that make it more difficult to counterfeit identity cards.

ThinFilm is supplied on either 75 mils (19 microns), or 1 mil (25 microns) PET carriers. The actual holographic or clear coatings that transfer to the card are very thin, only about .12 mils (3 microns). This thin layer of coatings will increase the card’s ability to withstand UV fading and dye migration but does little to improve the durability of the card.

Patch Laminate: Patch laminate also requires a dedicated laminator to apply the film to a card, but it provides a much higher level of durability than the O panel or ThinFilm. A patch laminate will increase scratch resistance and card life, and secure against counterfeiting and card alteration. This is why hundreds of millions of driver’s licenses and identity cards are produced with a patch laminate every year.

Patch laminates are available in clear and holographic (HRI) material and come in varying thicknesses. Patches are available in either 0.5 mil (12 microns), 0.6 mil (15 microns), or 1.0 mil (25 microns). The 1.0 mil (25 microns) patch can also be supplied with an additional UV blocking layer on request to increase card life by reducing fading/die migration from direct sunlight. In general, a 1mil patch laminate offers the highest level of durability.

IDP offers many laminating printers and film options. Laminate faster, create a stronger bond to the card, and save energy with IDP’s Direct Lamination Technology, available on the SMART-51L, SOLID-510L, SMART-70L and SMART-81L Systems

There’s much to see here. So, take your time, look around, and learn all there is to know about Photo ID Products. We hope you enjoy our site and take a moment to drop us a line.